[03]

2025

Project

[Design]

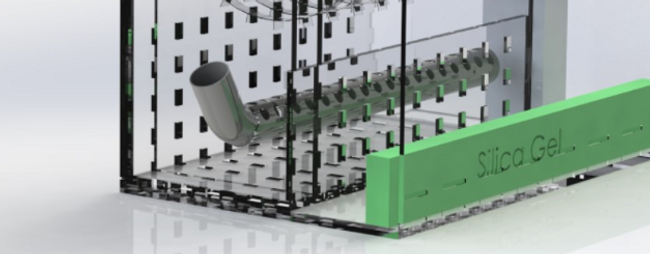

Side-Assembled View

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[03]

2025

Project

[Design]

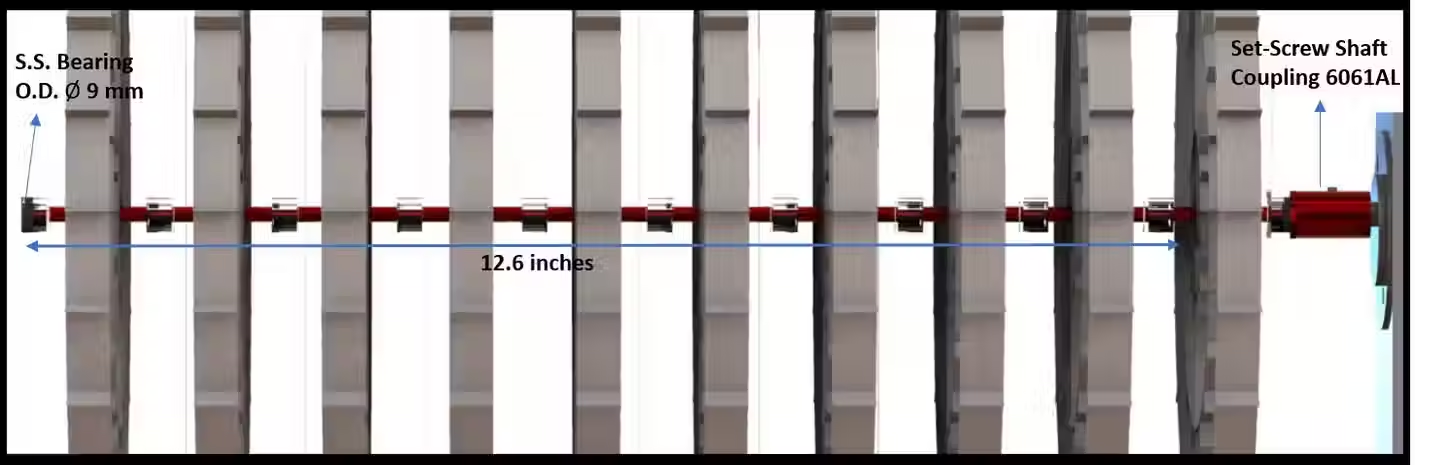

Semi-Assembled View

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[03]

2025

Project

[Design]

Power Generation Model

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Power Generation

[03]

2025

Project

[Design]

Range of Visal Facets and Variations of Project.

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Power Generation: Project Eva-Power

Engineer a scalabel, cubic-meter module that transforms hydration–dehydration cycles in hygroscopic cellophane into continuous mechanical rotation and reliable micro‑power generation.It relies on hydration and dehydration cycle of moisture-absorbing cellophane material; a hygroscopic material that has nanoscopic confinement of water.

Working Details

Evaporative Energy Capture: Exploited humidity differentials between a water reservoir and ambient air within a sealed chamber; weighted cellophane strips cyclically contracted and expanded to drive a central shaft. System tuning leveraged psychrometric modelling to optimise chamber ventilation rates, maintaining a stable humidity gradient even during day‑night swings.

Output: Modular 1 m³ units, each stacking 16 sub‑assemblies, provided ~1.3 W at a cost roughly triple pre‑scale solar. Extended field trials confirmed continuous power in 70–95 % RH climates and incorporated passive damping to prevent overspeed in tropical environments.

Rotor Assembly: Ten hygroscopic wheels on a common shaft produced ~78.9 mN of torque, delivering smooth rotational motion for micro‑generation. Carbon‑fibre shafting with low‑friction ceramic bearings curtailed drag, and an adjustable cam permitted torque scaling to match diverse electrical loads.

Prototyping & Materials R&D: Built multiple prototypes via SLA/SLS printing; micron‑precision laser‑cut cellophane and tested B. subtilis spore films achieving tensile responses 10× self‑weight. Comparative studies with PET, nylon, and cellulose‑xanthan blends verified cellophane’s superior cyclic durability over 50 000 actuation cycles.

FEA Validation: Applied Ansys multi‑physics to model humidity diffusion and coupled strip actuation, verifying wheel kinematics and friction losses. Correlation with high‑speed videography exhibited <4 % error in predicted angular velocity, underscoring solver accuracy

Tools and Skillset

SLA & SLS additive manufacturing

Precision laser micro‑cutting

Ansys FEA humidity‑coupled analysis

MATLAB friction‑loss modelling

PLC micro‑harvester circuit design

CNC machining & DFM practice

Embedded C programming

Team leadership