[08]

2025

Project

[Design]

Result Product

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[08]

2025

Project

[Design]

Whistle Candy : Product Geometry

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[08]

2025

Project

[Design]

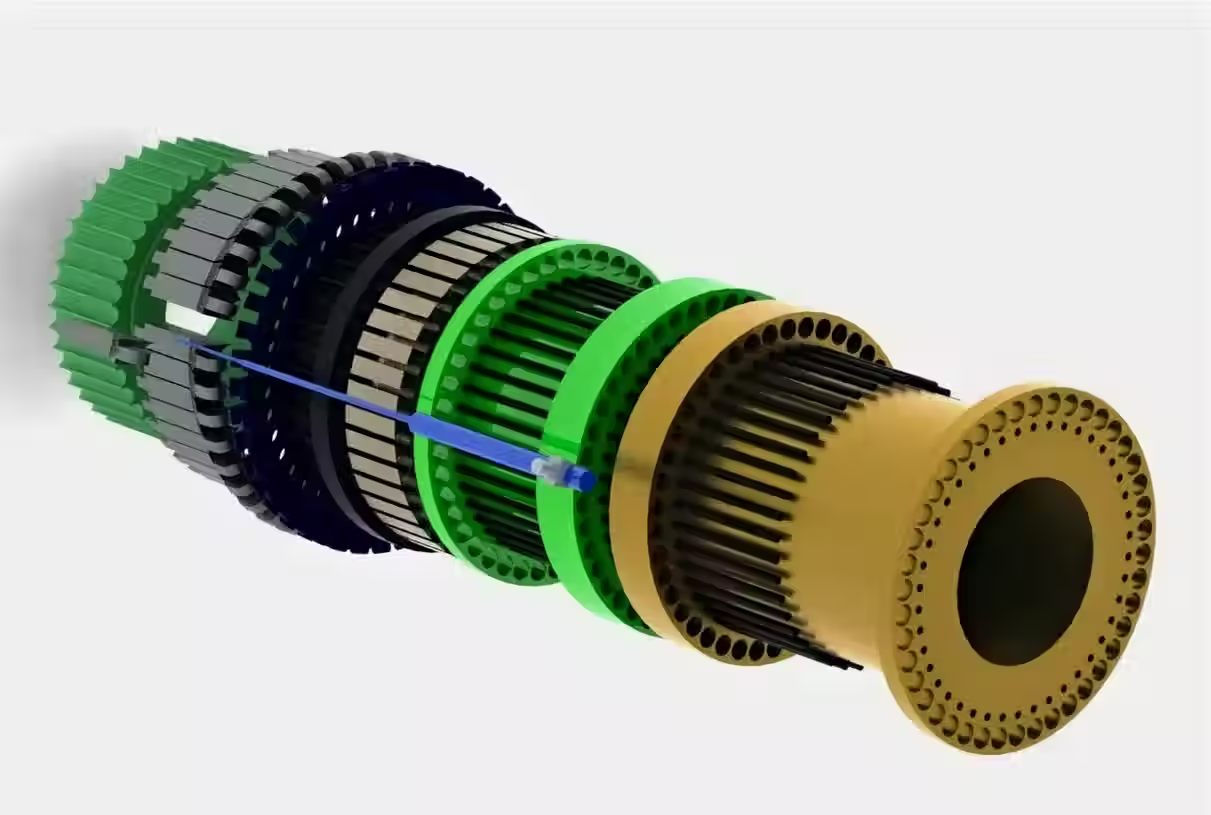

Exploded View of Single Punch Press of the Barrel-Die Machine

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Investment Casting Machine Design

[08]

2025

Project

[Design]

Range of Visal Facets and Variations of Project.

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Investment Casting-Barrel Die Press Machine

Design and build a whistle‑candy barrel die‑press that employs 42 rotating slot segments at ~100 rpm to mould hot syrup into whistle‑shaped candies, achieving aggressive OEM cost targets through sand‑cast prototypes and investment‑cast production tooling.

Working Details

Phase 1: Requirements & Budget Alignment – Engaged with the client to quantify throughput, cavity geometry, and lifetime expectations while working within a tightly capped capital budget typical of OEM confectionery suppliers. Cost‑down levers; including modular sub‑assemblies and local material sourcing; were identified early.

Phase 2: Cam Profile Formulation – Devised incremental segment hole punches via SVAJ analysis to shape a Critical Extreme Position (CEP) cam. The profile orchestrates a complete punch cycle across 21 active slots, while the complementary 21 slots reset the mechanism for continuous syrup intake, preventing cavity overfill.

Phase 3: Structural Design & Stress Audit – Modelled the 42‑segment barrel, cam, and slot punches in SolidWorks, then validated torsion and hoop stresses in Altair. A sand‑cast aluminium prototype confirmed manufacturability; final tooling used investment‑cast 316 L stainless for corrosion resistance and dimensional fidelity.

Phase 4 : Precision Machining & Modular Assembly – Individual punches were carved on VMC, HMC, and CNC lathes directly from G‑code, adhering to DFA/DFM principles for rapid change‑out. The 500 mm‑long barrel, weighing ~38 kg, assembles with keyed modules to facilitate maintenance and future cavity redesigns.

Factory acceptance trials demonstrated consistent mould fill, clean ejection, and dimensional tolerance within ±0.05 mm over 16‑hour endurance runs, validating both CEP timing and mechanical robustness.

Tools and Skillset

Investment & sand casting process design

Die‑press DFM/DFA strategies

SVAJ & CEP cam synthesis

SolidWorks and Altair torsion/hoop stress FEA

VMC/HMC G‑code programming

Modular punch fabrication & assembly

Material property & HB/HK/Vickers hardness testing

OEM cost‑optimisation & production scaling