[10]

2025

Project

[Design]

Schematic-Analysis Elaboration

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[10]

2025

Project

[Design]

Conceptulisation of model

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[10]

2025

Project

[Design]

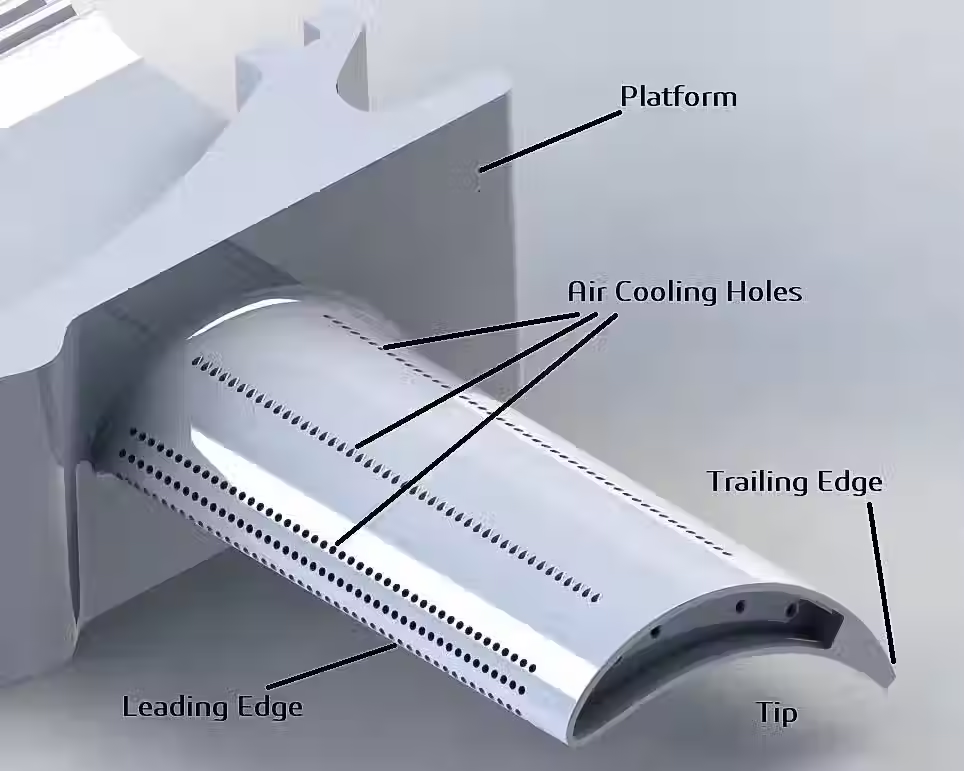

Turbine Blade prototype

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Blade Thermal Barrier Coating

[10]

2025

Project

[Design]

Range of Visal Facets and Variations of Project.

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Thermal Interface Material - Barrier Coating

Engineer a thermal‑barrier coating (TBC) configuration for a gas‑turbine blade that limits base‑metal temperature to ≤ 1050 °C while withstanding a 1400 °C gas stream and maintaining manufacturability, durability, and weight targets.

Working Details

Phase 1: Gas‑Path Modelling – Modelled the 1400 °C gas flow from compressor exit through turbine blades to the nozzle under steady‑state, incompressible assumptions; a constant convection coefficient was applied along the blade fin to establish baseline heat flux.

Phase 2: Material Down‑Select & Thickness Optimisation – Screened candidate TBC stacks; YSZ–ceria, zirconia, and aerogel; against thermal conductivity, sintering resistance, and cost. Calculated thicknesses that balanced durability, weight, and expense, then computed heat transfer and enthalpy savings for each multilayer configuration.

Phase 3: MATLAB Prototype Coding – Implemented the optimised bare‑blade model in MATLAB PlotLib, iterating parametric sweeps of coating combinations to visualise temperature fields and quantify effectiveness across operating points.

Phase 4: Experimental Validation – Applied the selected TBC to a surrogate heat‑exchanger coupon replicating blade geometry. Testing confirmed the refrigeration‑equivalent heat dissipation reduced metal temperature from 1400 °C to ~1050 °C, matching simulation within ±3 %.

These steps verified that the chosen YSZ–ceria stack, at a tuned thickness, meets thermal targets without excessive mass penalty and is compatible with existing turbine maintenance cycles.

Tools and Skillset

MATLAB / Simulink thermal modelling

MATLAB PlotLib temperature visualisation

CFD in MATLAB & SolidWorks Flow Sim

Ansys Fluent conjugate analysis

Fusion 360 CAD integration

Thermal‑barrier materials selection

Coating thickness optimisation & parametric sweep